JIAOZUO ZHONGWEI SPECIAL PRODUCTS PHARMACEUTICAL CO.,LTD

<progress id="ecuua"><menuitem id="ecuua"></menuitem></progress>

| Availability: | |

|---|---|

PVPP is a stabilizer for suspensions. There are two different grades of PVPP, food grade PVPP & pharmaceutical grade PVPP. PVPP is hygroscopic and insoluble in water and all other common solvents, but it swells rapidly in aqueous solutions without any gel.

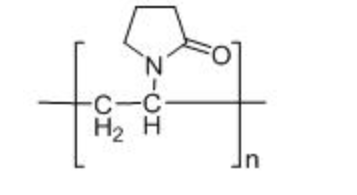

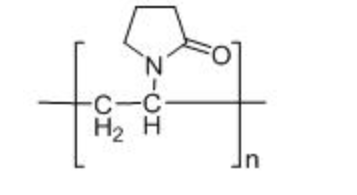

Structure formula:

Appearance: White or yellowish-white powder

Application: It can be applied to dark beer, white beer and so on.

PVPP can significantly improve the color, taste and stability of beer.

PVPP | |

pH value | 5.0-8.0 |

Soluble components(%) | ≤1.0 |

Loss on Drying (%) | ≤5.0 |

Residue on Ignition(%) | ≤0.1 |

Effectiveness of adsorption (Catechin%) | ≥55 |

NVP mg/kg | <10 |

Heavy Metals (ppm) | ≤10 |

Arsenic(ppm) | <2 |

Lead(ppm) | <2 |

Nitrogen (%) | 11.0-12.8 |

In the Beverage Industry:Polyvinylpyrrolidone (PVP) is commonly employed as a clarifying agent in the production of beverages such as beer and wine. It efficiently eliminates suspended solids, haze-causing proteins, and polyphenols, thereby reducing turbidity and significantly enhancing both the visual clarity and stability of the final product. This results in beverages that are not only more visually appealing but also smoother in flavor and more enjoyable to consume.

In Tea-Based Drinks (e.g., Green Tea):PVP is also effective in preserving the clarity of tea beverages by preventing cloudiness. It binds with polyphenolic compounds to form insoluble complexes, which can then be removed, improving both color and taste profiles while maintaining transparency during storage.

PVPP – Crosslinked and Water-Insoluble Variant:Unlike water-soluble PVP, Polyvinylpolypyrrolidone (PVPP) is an insoluble, crosslinked version with a unique three-dimensional network. This structure grants it chemical resistance (insoluble in water, acids, alkalis, and common solvents) while retaining beneficial properties like adsorption and complexation. PVPP is widely utilized in industries such as pharmaceuticals, food processing, and animal feed.

In Biopharmaceuticals:PVPP offers excellent physiological compatibility and inertness, making it suitable for various medical applications. It is commonly used as a tablet disintegrant, sustained-release excipient, and component in dialysis membranes. Upon absorbing moisture, PVPP rapidly expands, creating mechanical pressure that causes tablets or capsules to disintegrate into fine particles. This facilitates faster dissolution and absorption, thereby enhancing the drug’s bioavailability in the body.

Crospovidone (PVPP) is typically packaged in 20 kg high-density polyethylene (HDPE) plastic drums or fiber drums, each securely lined with two layers of polyethylene (PE) inner bags to prevent contamination and moisture ingress. This double-layer protection ensures product integrity throughout handling and storage.

Tailored packaging solutions are available upon request to meet specific customer needs or regulatory requirements, including smaller pack sizes, vacuum-sealed bags, or palletized bulk packaging options for large-scale manufacturing.

Store in tightly sealed containers to protect against moisture and environmental contaminants. Keep in a cool, dry, and well-ventilated storage area, away from sources of heat, direct sunlight, and strong oxidizing agents.

Avoid exposure to high humidity or fluctuating temperatures, which may affect the product's adsorption efficiency and flowability. Under recommended storage conditions, PVPP maintains its physical and functional stability for an extended shelf life.

When stored properly, the product typically retains optimal performance for at least 24 months from the date of manufacture.

A1: Crospovidone, also known as PVPP (Polyvinylpolypyrrolidone), is the crosslinked, water-insoluble form of PVP. While PVP is water-soluble and often used in pharmaceutical formulations, PVPP’s unique network structure makes it ideal for adsorption-based applications such as beverage clarification, due to its ability to bind and remove haze-forming polyphenols and proteins.

A2: PVPP is primarily used as a clarifying and stabilizing agent in beverages such as beer, wine, and tea. It improves beverage clarity, removes polyphenols and proteins that cause haze, and enhances the overall color, flavor, and shelf stability of the product.

A3: PVPP adsorbs polyphenols, such as catechins, that react with proteins to form haze. By binding these polyphenols and forming insoluble complexes, PVPP removes them from the liquid, resulting in a clearer and more stable beer.

A4: Yes, food-grade PVPP is non-toxic, physiologically inert, and meets international food safety standards. It is commonly used in beverages and is considered safe when used within regulated limits.

PVPP is a stabilizer for suspensions. There are two different grades of PVPP, food grade PVPP & pharmaceutical grade PVPP. PVPP is hygroscopic and insoluble in water and all other common solvents, but it swells rapidly in aqueous solutions without any gel.

Structure formula:

Appearance: White or yellowish-white powder

Application: It can be applied to dark beer, white beer and so on.

PVPP can significantly improve the color, taste and stability of beer.

PVPP | |

pH value | 5.0-8.0 |

Soluble components(%) | ≤1.0 |

Loss on Drying (%) | ≤5.0 |

Residue on Ignition(%) | ≤0.1 |

Effectiveness of adsorption (Catechin%) | ≥55 |

NVP mg/kg | <10 |

Heavy Metals (ppm) | ≤10 |

Arsenic(ppm) | <2 |

Lead(ppm) | <2 |

Nitrogen (%) | 11.0-12.8 |

In the Beverage Industry:Polyvinylpyrrolidone (PVP) is commonly employed as a clarifying agent in the production of beverages such as beer and wine. It efficiently eliminates suspended solids, haze-causing proteins, and polyphenols, thereby reducing turbidity and significantly enhancing both the visual clarity and stability of the final product. This results in beverages that are not only more visually appealing but also smoother in flavor and more enjoyable to consume.

In Tea-Based Drinks (e.g., Green Tea):PVP is also effective in preserving the clarity of tea beverages by preventing cloudiness. It binds with polyphenolic compounds to form insoluble complexes, which can then be removed, improving both color and taste profiles while maintaining transparency during storage.

PVPP – Crosslinked and Water-Insoluble Variant:Unlike water-soluble PVP, Polyvinylpolypyrrolidone (PVPP) is an insoluble, crosslinked version with a unique three-dimensional network. This structure grants it chemical resistance (insoluble in water, acids, alkalis, and common solvents) while retaining beneficial properties like adsorption and complexation. PVPP is widely utilized in industries such as pharmaceuticals, food processing, and animal feed.

In Biopharmaceuticals:PVPP offers excellent physiological compatibility and inertness, making it suitable for various medical applications. It is commonly used as a tablet disintegrant, sustained-release excipient, and component in dialysis membranes. Upon absorbing moisture, PVPP rapidly expands, creating mechanical pressure that causes tablets or capsules to disintegrate into fine particles. This facilitates faster dissolution and absorption, thereby enhancing the drug’s bioavailability in the body.

Crospovidone (PVPP) is typically packaged in 20 kg high-density polyethylene (HDPE) plastic drums or fiber drums, each securely lined with two layers of polyethylene (PE) inner bags to prevent contamination and moisture ingress. This double-layer protection ensures product integrity throughout handling and storage.

Tailored packaging solutions are available upon request to meet specific customer needs or regulatory requirements, including smaller pack sizes, vacuum-sealed bags, or palletized bulk packaging options for large-scale manufacturing.

Store in tightly sealed containers to protect against moisture and environmental contaminants. Keep in a cool, dry, and well-ventilated storage area, away from sources of heat, direct sunlight, and strong oxidizing agents.

Avoid exposure to high humidity or fluctuating temperatures, which may affect the product's adsorption efficiency and flowability. Under recommended storage conditions, PVPP maintains its physical and functional stability for an extended shelf life.

When stored properly, the product typically retains optimal performance for at least 24 months from the date of manufacture.

A1: Crospovidone, also known as PVPP (Polyvinylpolypyrrolidone), is the crosslinked, water-insoluble form of PVP. While PVP is water-soluble and often used in pharmaceutical formulations, PVPP’s unique network structure makes it ideal for adsorption-based applications such as beverage clarification, due to its ability to bind and remove haze-forming polyphenols and proteins.

A2: PVPP is primarily used as a clarifying and stabilizing agent in beverages such as beer, wine, and tea. It improves beverage clarity, removes polyphenols and proteins that cause haze, and enhances the overall color, flavor, and shelf stability of the product.

A3: PVPP adsorbs polyphenols, such as catechins, that react with proteins to form haze. By binding these polyphenols and forming insoluble complexes, PVPP removes them from the liquid, resulting in a clearer and more stable beer.

A4: Yes, food-grade PVPP is non-toxic, physiologically inert, and meets international food safety standards. It is commonly used in beverages and is considered safe when used within regulated limits.