JIAOZUO ZHONGWEI SPECIAL PRODUCTS PHARMACEUTICAL CO.,LTD

<progress id="6vol5"><menuitem id="6vol5"></menuitem></progress>

| Availability: | |

|---|---|

Crosslinked Polyvinylpyrrolidone (PVPP) can be regarded as linear PVPVP molecular chains that have been interconnected either physically or chemically. PVPPs synthesized through various methods exhibit distinct properties due to differences in crosslinking techniques and extents. Depending on the degree of crosslinking, PVPP ranges from highly water-absorbent resins (low crosslinking), to absorbent gels (moderate crosslinking), and to insoluble substances (high crosslinking). Unlike PVP, which is a water-soluble polymer, PVPP is capable of only swelling in water rather than dissolving completely.Pharmaceutical grade crosslinked povidone (PVPP), with a purity of 100%, is ideal as a super disintegrant.

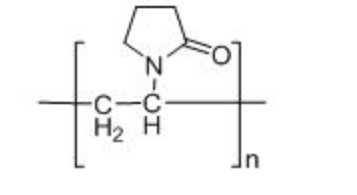

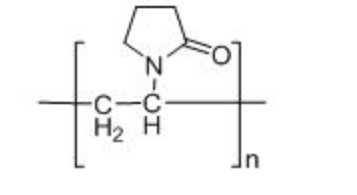

Structure formula:

Appearance: White or yellowish-white powder

CDE register number: F20209990877

Application: Insoluble in water or common organic solvents, the powder particles are porous microstructures

with high specific surface area.

As a super disintegretant, it will not form gel and can effectively improve the disintegration time.

PVPP XL(Type A) | PVPP XL-10(Type B) | |

pH value | 5.0-8.0 | 5.0-8.0 |

Water-soluble substances(%) | ≤1.5 | ≤1.5 |

Loss on Drying (%) | ≤5.0 | ≤5.0 |

Residue on Ignition(%) | ≤0.1 | ≤0.1 |

Peroxides(ppm) | ≤400 | ≤400 |

NVP (ppm) | ≤10 | ≤10 |

Heavy Metals (ppm) | ≤10 | ≤10 |

Nitrogen (%) | 11.5-12.8 | 11.5-12.8 |

Average particle(D50) (μm) | 80-180 | 30-50 |

All products comply with Ph. Eur, USP/NF, JP,BP certificate of analysis.

For both PVPP XL(Type A) and PVPP XL–10(Type B), the pH value ranges from 5.0 to 8.0. The content of water-soluble substances is less than or equal to 1.5% for both types. The loss on drying is controlled to be less than or equal to 5.0%. The residue on ignition is less than 0.1% for both products.

The level of peroxides is kept below 400 parts per million (ppm). Non-volatile particles (NVP) are limited to less than 10 ppm, and the content of heavy metals is restricted to a maximum of 10 ppm.

Nitrogen content varies slightly between the two types, with PVPP XL(Type A) having 11.5-12.8% and PVPP XL–10(Type B) having 11.5-12.8%.

The average particle size (D50) for PVPP XL(Type A) is between 80 and 180 micrometers, while for PVPP XL–10(Type B) it ranges from 30 to 50 micrometers.

Clarifying and Stabilizing Agents:

In the beverage industry, PVP is utilized as a clarifying agent, particularly in the production of wine and beer. It efficiently removes suspended particles, proteins, and polyphenols, reducing turbidity and enhancing the transparency and stability of beverages. This clarification not only improves the appearance but also enhances the flavor, resulting in a clearer and more palatable final product.

For drinks like green tea, PVP helps maintain clarity and prevents cloudiness. It functions by binding with polyphenolic compounds to form insoluble precipitates, thus removing components that affect the drink's color and taste.

Additional Applications:

PVPP, as an insoluble cross-linked polymer, features a unique reticulated structure and overcomes the solubility limitations of PVP. It is insoluble in acids, bases, and common organic solvents, unlike PVP. PVPP boasts excellent physiological safety, water absorption, insolubility, and complexing capabilities. It finds extensive use in pharmaceuticals, food, personal care, and feed industries.

In the pharmaceutical sector, PVPP offers good physiological inertia and biocompatibility. It serves as a disintegrating agent, drug delivery vehicle, and for blood dialysis membranes. Upon water absorption, PVPP swells, allowing tablets (capsules) to withstand high pressure and then disintegrate into small, hard-to-assess grains, thereby enhancing bioavailability.

In the personal care industry, PVPP can be used as a moisturizer in high-end cosmetics, hydrating the skin, preserving fragrance, alleviating pain, and reducing irritation. In toothpaste, PVPP can clean the mouth and reduce inflammation.

A: Crospovidone (PVPP) is a pharmaceutical-grade crosslinked Polyvinylpyrrolidone, serving as a super disintegrant. It is insoluble in water or common organic solvents and features porous microstructures with a high specific surface area. This makes it ideal for use as a disintegrating agent, drug delivery vehicle, and in blood dialysis membranes.

A: Crospovidone (PVPP) should be stored in tight containers to maintain its quality. It's recommended to keep it in a cool, dry place away from direct sunlight and extreme temperatures to ensure stability and efficacy.

A: In personal care, Crospovidone (PVPP) can be used as a moisturizer in high-end cosmetics, hydrating the skin, preserving fragrance, alleviating pain, and reducing irritation. It also finds use in toothpaste for cleaning the mouth and reducing inflammation.

A: Unlike PVP, which is a water-soluble polymer, Crospovidone (PVPP) is capable of only swelling in water rather than dissolving completely. This property makes PVPP suitable for applications where controlled release and stability are crucial.

Crosslinked Polyvinylpyrrolidone (PVPP) can be regarded as linear PVPVP molecular chains that have been interconnected either physically or chemically. PVPPs synthesized through various methods exhibit distinct properties due to differences in crosslinking techniques and extents. Depending on the degree of crosslinking, PVPP ranges from highly water-absorbent resins (low crosslinking), to absorbent gels (moderate crosslinking), and to insoluble substances (high crosslinking). Unlike PVP, which is a water-soluble polymer, PVPP is capable of only swelling in water rather than dissolving completely.Pharmaceutical grade crosslinked povidone (PVPP), with a purity of 100%, is ideal as a super disintegrant.

Structure formula:

Appearance: White or yellowish-white powder

CDE register number: F20209990877

Application: Insoluble in water or common organic solvents, the powder particles are porous microstructures

with high specific surface area.

As a super disintegretant, it will not form gel and can effectively improve the disintegration time.

PVPP XL(Type A) | PVPP XL-10(Type B) | |

pH value | 5.0-8.0 | 5.0-8.0 |

Water-soluble substances(%) | ≤1.5 | ≤1.5 |

Loss on Drying (%) | ≤5.0 | ≤5.0 |

Residue on Ignition(%) | ≤0.1 | ≤0.1 |

Peroxides(ppm) | ≤400 | ≤400 |

NVP (ppm) | ≤10 | ≤10 |

Heavy Metals (ppm) | ≤10 | ≤10 |

Nitrogen (%) | 11.5-12.8 | 11.5-12.8 |

Average particle(D50) (μm) | 80-180 | 30-50 |

All products comply with Ph. Eur, USP/NF, JP,BP certificate of analysis.

For both PVPP XL(Type A) and PVPP XL–10(Type B), the pH value ranges from 5.0 to 8.0. The content of water-soluble substances is less than or equal to 1.5% for both types. The loss on drying is controlled to be less than or equal to 5.0%. The residue on ignition is less than 0.1% for both products.

The level of peroxides is kept below 400 parts per million (ppm). Non-volatile particles (NVP) are limited to less than 10 ppm, and the content of heavy metals is restricted to a maximum of 10 ppm.

Nitrogen content varies slightly between the two types, with PVPP XL(Type A) having 11.5-12.8% and PVPP XL–10(Type B) having 11.5-12.8%.

The average particle size (D50) for PVPP XL(Type A) is between 80 and 180 micrometers, while for PVPP XL–10(Type B) it ranges from 30 to 50 micrometers.

Clarifying and Stabilizing Agents:

In the beverage industry, PVP is utilized as a clarifying agent, particularly in the production of wine and beer. It efficiently removes suspended particles, proteins, and polyphenols, reducing turbidity and enhancing the transparency and stability of beverages. This clarification not only improves the appearance but also enhances the flavor, resulting in a clearer and more palatable final product.

For drinks like green tea, PVP helps maintain clarity and prevents cloudiness. It functions by binding with polyphenolic compounds to form insoluble precipitates, thus removing components that affect the drink's color and taste.

Additional Applications:

PVPP, as an insoluble cross-linked polymer, features a unique reticulated structure and overcomes the solubility limitations of PVP. It is insoluble in acids, bases, and common organic solvents, unlike PVP. PVPP boasts excellent physiological safety, water absorption, insolubility, and complexing capabilities. It finds extensive use in pharmaceuticals, food, personal care, and feed industries.

In the pharmaceutical sector, PVPP offers good physiological inertia and biocompatibility. It serves as a disintegrating agent, drug delivery vehicle, and for blood dialysis membranes. Upon water absorption, PVPP swells, allowing tablets (capsules) to withstand high pressure and then disintegrate into small, hard-to-assess grains, thereby enhancing bioavailability.

In the personal care industry, PVPP can be used as a moisturizer in high-end cosmetics, hydrating the skin, preserving fragrance, alleviating pain, and reducing irritation. In toothpaste, PVPP can clean the mouth and reduce inflammation.

A: Crospovidone (PVPP) is a pharmaceutical-grade crosslinked Polyvinylpyrrolidone, serving as a super disintegrant. It is insoluble in water or common organic solvents and features porous microstructures with a high specific surface area. This makes it ideal for use as a disintegrating agent, drug delivery vehicle, and in blood dialysis membranes.

A: Crospovidone (PVPP) should be stored in tight containers to maintain its quality. It's recommended to keep it in a cool, dry place away from direct sunlight and extreme temperatures to ensure stability and efficacy.

A: In personal care, Crospovidone (PVPP) can be used as a moisturizer in high-end cosmetics, hydrating the skin, preserving fragrance, alleviating pain, and reducing irritation. It also finds use in toothpaste for cleaning the mouth and reducing inflammation.

A: Unlike PVP, which is a water-soluble polymer, Crospovidone (PVPP) is capable of only swelling in water rather than dissolving completely. This property makes PVPP suitable for applications where controlled release and stability are crucial.